Assessing Leading High Precision Mineral Casting Machine Base Manufacturers: ZHHIMG's Positioning and Core Competencies

JINAN, SHANDONG, CHINA, December 4, 2025 /EINPresswire.com/ -- The Evolving Landscape of Precision Manufacturing and Machine Tool Technology

The global manufacturing sector is undergoing significant transformation, driven by the pursuit of higher precision, increased automation, and enhanced operational stability. These developments are especially evident in the machine tool industry, where the technical objective is to achieve and maintain nanometer-level accuracy while reducing both dynamic and thermal disturbances. In this context, traditional materials such as cast iron and steel are approaching their inherent performance limitations, particularly in ultra-precision applications. This growing need for advanced structural materials has contributed to the adoption of specialized solutions provided by the Top 5 Mineral Casting Machine Base Manufacturers.

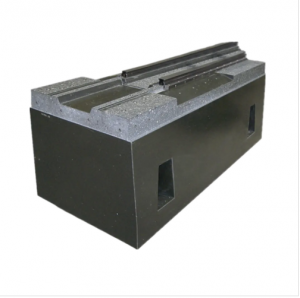

Mineral casting—commonly referred to as polymer concrete or epoxy granite—is a composite material engineered from selected mineral aggregates bonded with epoxy resin systems. Its characteristics, including strong vibration damping capability, thermal stability, and design flexibility, make it a key material for constructing high-speed, high-accuracy equipment such as five-axis machining centers, precision grinding machines, and metrology systems.

Deep Dive into Mineral Casting Technology and Its Advantages

Mineral casting is not simply an alternative to metal; it represents a different structural approach to machine base engineering. Its material science advantages support high-performance machinery:

Vibration Absorption (Damping): With damping ratios significantly higher than cast iron, mineral casting dissipates vibration rapidly, contributing to consistent machining accuracy, improved surface quality, and reduced tool wear.

Thermal Stability: With a lower coefficient of thermal expansion and very low thermal conductivity, mineral casting mitigates thermal gradients and reduces distortion, an important factor in continuous or heavy-duty machine operation.

Chemical Resistance and Durability: The non-porous surface is resistant to coolants, oils, and abrasive particles, helping preserve long-term dimensional stability.

Integration and Customization: As a near-net-shape process, mineral casting allows components such as internal channels, inserts, and leveling systems to be incorporated during molding, reducing subsequent machining and simplifying assembly.

The Rise of Mineral Casting and Global Industry Trends

Competition among high-precision machine base manufacturers increasingly centers on material science expertise and specialized production capabilities. Market trends indicate growing demand for custom, monolithic structures with complex internal features, such as integrated cable routing and temperature management systems. Consequently, machine builders seek suppliers with both material expertise and the ability to meet international quality and environmental standards while providing scalable production capacity.

ZHHIMG’s Technical Depth and Manufacturing Heritage

Zhonghui Intelligent Manufacturing (Jinan) Co., Ltd. (ZHHIMG) has been active in the field of non-metallic ultra-precision engineering since the 1980s. Initially focused on high-precision granite components, the company has developed extensive expertise in material behavior, thermal control, long-term stability, and precision finishing—knowledge that is foundational to producing mineral casting machine bases.

ZHHIMG's Core Advantages: Capacity, Scale, and Certification Excellence

Manufacturing Scale and Supply Chain Reliability: With two manufacturing facilities in Shandong Province, ZHHIMG supports high-volume production of mineral casting and granite components, with capacity reaching up to 10,000 sets per month. This capability helps meet the needs of major machine tool manufacturers requiring consistent supply and reliable production timelines.

Technological Capability in Large-Format Components: ZHHIMG can produce large, monolithic components, including single pieces up to 100 tons or 20 meters in length. This is particularly valuable for large-format precision equipment, such as gantry systems, where structural rigidity and geometric consistency are essential.

Integrated Quality and Compliance Systems: ZHHIMG maintains international certifications including:

ISO 9001 (Quality Management)

ISO 14001 (Environmental Management)

ISO 45001 (Occupational Health and Safety)

CE Mark

These certifications demonstrate structured adherence to global standards and support quality consistency across production processes.

Applications and Case Studies: The ZHHIMG Footprint in High-Tech Industries

ZHHIMG’s mineral casting machine bases support applications across several high-precision sectors:

Semiconductor and Microelectronics: The vibration damping capabilities help maintain stability during wafer processing, alignment, and inspection stages.

High-End Machine Tools: Used in multi-axis CNC machines, laser systems, and high-precision grinding equipment, contributing to reduced thermal drift and stable machine performance.

Metrology and Advanced Quality Control: The low thermal expansion and stability support Coordinate Measuring Machines (CMMs) and optical measurement systems, helping maintain measurement accuracy under varying environmental conditions.

Long-term collaborations described in the company’s project documentation highlight ZHHIMG’s role in supporting next-generation equipment development.

Conclusion: A Commitment to Foundational Precision

The future of high-accuracy manufacturing depends heavily on the structural foundation supporting the equipment. As industries continue to advance toward higher machining speeds, greater complexity, and tighter tolerances, the demand for mineral casting technology will increase. ZHHIMG’s combination of specialized knowledge in non-metallic ultra-precision materials, large-scale production capability, integrated quality systems, and customization capacity positions it as a significant contributor among the Top 5 Mineral Casting Machine Base Manufacturers. The company’s technical competence contributes to the foundational stability required in advanced manufacturing environments.

For more information on ZHHIMG’s precision manufacturing solutions, visit: https://www.zhhimg.com/

The global manufacturing sector is undergoing significant transformation, driven by the pursuit of higher precision, increased automation, and enhanced operational stability. These developments are especially evident in the machine tool industry, where the technical objective is to achieve and maintain nanometer-level accuracy while reducing both dynamic and thermal disturbances. In this context, traditional materials such as cast iron and steel are approaching their inherent performance limitations, particularly in ultra-precision applications. This growing need for advanced structural materials has contributed to the adoption of specialized solutions provided by the Top 5 Mineral Casting Machine Base Manufacturers.

Mineral casting—commonly referred to as polymer concrete or epoxy granite—is a composite material engineered from selected mineral aggregates bonded with epoxy resin systems. Its characteristics, including strong vibration damping capability, thermal stability, and design flexibility, make it a key material for constructing high-speed, high-accuracy equipment such as five-axis machining centers, precision grinding machines, and metrology systems.

Deep Dive into Mineral Casting Technology and Its Advantages

Mineral casting is not simply an alternative to metal; it represents a different structural approach to machine base engineering. Its material science advantages support high-performance machinery:

Vibration Absorption (Damping): With damping ratios significantly higher than cast iron, mineral casting dissipates vibration rapidly, contributing to consistent machining accuracy, improved surface quality, and reduced tool wear.

Thermal Stability: With a lower coefficient of thermal expansion and very low thermal conductivity, mineral casting mitigates thermal gradients and reduces distortion, an important factor in continuous or heavy-duty machine operation.

Chemical Resistance and Durability: The non-porous surface is resistant to coolants, oils, and abrasive particles, helping preserve long-term dimensional stability.

Integration and Customization: As a near-net-shape process, mineral casting allows components such as internal channels, inserts, and leveling systems to be incorporated during molding, reducing subsequent machining and simplifying assembly.

The Rise of Mineral Casting and Global Industry Trends

Competition among high-precision machine base manufacturers increasingly centers on material science expertise and specialized production capabilities. Market trends indicate growing demand for custom, monolithic structures with complex internal features, such as integrated cable routing and temperature management systems. Consequently, machine builders seek suppliers with both material expertise and the ability to meet international quality and environmental standards while providing scalable production capacity.

ZHHIMG’s Technical Depth and Manufacturing Heritage

Zhonghui Intelligent Manufacturing (Jinan) Co., Ltd. (ZHHIMG) has been active in the field of non-metallic ultra-precision engineering since the 1980s. Initially focused on high-precision granite components, the company has developed extensive expertise in material behavior, thermal control, long-term stability, and precision finishing—knowledge that is foundational to producing mineral casting machine bases.

ZHHIMG's Core Advantages: Capacity, Scale, and Certification Excellence

Manufacturing Scale and Supply Chain Reliability: With two manufacturing facilities in Shandong Province, ZHHIMG supports high-volume production of mineral casting and granite components, with capacity reaching up to 10,000 sets per month. This capability helps meet the needs of major machine tool manufacturers requiring consistent supply and reliable production timelines.

Technological Capability in Large-Format Components: ZHHIMG can produce large, monolithic components, including single pieces up to 100 tons or 20 meters in length. This is particularly valuable for large-format precision equipment, such as gantry systems, where structural rigidity and geometric consistency are essential.

Integrated Quality and Compliance Systems: ZHHIMG maintains international certifications including:

ISO 9001 (Quality Management)

ISO 14001 (Environmental Management)

ISO 45001 (Occupational Health and Safety)

CE Mark

These certifications demonstrate structured adherence to global standards and support quality consistency across production processes.

Applications and Case Studies: The ZHHIMG Footprint in High-Tech Industries

ZHHIMG’s mineral casting machine bases support applications across several high-precision sectors:

Semiconductor and Microelectronics: The vibration damping capabilities help maintain stability during wafer processing, alignment, and inspection stages.

High-End Machine Tools: Used in multi-axis CNC machines, laser systems, and high-precision grinding equipment, contributing to reduced thermal drift and stable machine performance.

Metrology and Advanced Quality Control: The low thermal expansion and stability support Coordinate Measuring Machines (CMMs) and optical measurement systems, helping maintain measurement accuracy under varying environmental conditions.

Long-term collaborations described in the company’s project documentation highlight ZHHIMG’s role in supporting next-generation equipment development.

Conclusion: A Commitment to Foundational Precision

The future of high-accuracy manufacturing depends heavily on the structural foundation supporting the equipment. As industries continue to advance toward higher machining speeds, greater complexity, and tighter tolerances, the demand for mineral casting technology will increase. ZHHIMG’s combination of specialized knowledge in non-metallic ultra-precision materials, large-scale production capability, integrated quality systems, and customization capacity positions it as a significant contributor among the Top 5 Mineral Casting Machine Base Manufacturers. The company’s technical competence contributes to the foundational stability required in advanced manufacturing environments.

For more information on ZHHIMG’s precision manufacturing solutions, visit: https://www.zhhimg.com/

Zhonghui inteligent Manufacturing (Jinan) Group Co., Ltd.

Zhonghui inteligent Manufacturing (Jinan) Group Co., Ltd.

+86 199 6999 1659

info@zhhimg.com

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.